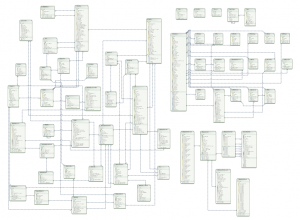

Q.MACS uses a pretty complex data model. In fact, everything that the system transmits to the welding machines, are just parameters for the welding of various welds.

Usually in systems such as Q.MACS all these parameters are collected into packages – called Jobs. Job contains the parameter settings for the welding, divided into groups depending on the phase of the welding process: start, basic and final. In other words, – job is a welding scenario.

So why do we still need further items, although they are nothing more than a series of jobs?

Imagine the following situation: You have created a number of jobs for one weld, then for the next one and so on, up to the welding of an entire component. Later you may have to create a similar set for the welding of another component, or even for several components. And even if you save every job with an own name, from a certain point the orientation within so many jobs will be problematically and finally even impossible.

Q.MACS data model reflect the structure of real welded objects

Wouldn’t it be easier, you might think, to divide these jobs into groups? So these groups do not only vary by name but also are structured hierarchically, i.e. that one group can contain others (sub-groups, e.g. file folders in Windows).

Surely it would!

And exactly that’s why in Q.MACS jobs can be collected in so-called containers (or welding scenarios). Thereby, the structure of container corresponds to the structure of real objects.

Joint technology defines the structure of a typical welded joint

After analyzing the operations of the real production, we came to the conclusion that for a convenient organized workflow we do require various job containers.

For example: joints, which have the same structure (or consist of identical passes), can be welded in different types of components.

This led to the creation of Joint Technology – a template, which describes the structure (or a welding scenario) of a typical welded joint.

Once it is necessary that certain welds need to be done in the same way, you can, once created a Joint Technology, based on it, weld the same joints for different welded structures.

Using Joint technology ensures the compliance to the WPS

Using the joint technology provides you another important advantage – the compliance to the Welding Procedure Specifications (WPS).

Ones you enter the data from the WPS into Technology, Q.MACS will “adapt” (taking into account the restrictions that WPS sets up for this type of welded joint) all the jobs automatically.

Within the analysis of produced welds you can compare the stored values of the welding parameters with these WPS-restrictions. This means that you can always control weather or not the weld quality corresponds to the within WPS defined requirements for the joints of this type.

Welded structure – a scenario for welding an entire construction

Logically, it may be assumed that by using the Joint Technology a welding scenario of an entire welding construction (e.g. component) can be created.

Welded structure is such a container, in which each Joint of a welded construction is associated with a particular Joint Technology, which describes the structure of this joint (i.e. the weld passes, and thus all the jobs).

Of course while defining each joint of the welded structure you can use a previously created Joint technology. And not just for one but also for various welded constructions.

Once the Welded structure loaded on the machine, you’re getting a complete set of jobs for all passes of all joints (in other words, the entire welding scenario) for this construction.

After correcting the job parameters within the Joint Technology, all changes are automatically applied in all Joints with similar Technology and therefore for all Welded structures that contain the Joints of this type.

Welding tasks Group – a scenario of welding of a certain construction on multiple machines

It is not always comfortable (or even possible), to weld all welds (welding passes) of one construction on a single machine.

And this is why we developed the Welding Task Group – a container in which all welding passes that make up the scenario of a welded structure, are divided into groups (called tasks), in which each task (i.e. a set of welding passes) is performed on a separate machine.

While creating a Welding Tasks Group a particular Welded Structure forms its basis. Thereby the system controls that all Tasks of the group include all welding passes of this structure, and that no pass is used twice (for different tasks).

Of course you can create several different Task Groups for the welding of structures of the same type and thus receive several different scenarios for the welding of the same constructions on different machines.

Thus the Welding Tasks Group is a scenario of welding of a certain construction on multiple machines. And (of course) there may be several such scenarios!

And if in the future you may change the settings of the Welded Structure, these changes will be adopted automatically within all groups containing tasks for welding these constructions.

While transferring of welding settings to the machine, you can select the Task (corresponding to the machine type) from the group (according to the welded structure-type) and upload the machine with all Jobs (of all Welding Passes), which contain this Task.

With the Welding Program you can perform tasks for welding of constructions of various types on one single machine

Now we’ve learned some types of jobs containers and thus different possibilities for uploading the machine. These are:

- Joint Technology, collecting welding passes

- Welded structure, consisting of several Joints

- Welding Tasks Group, in which each Task is a set of Passes to weld on a single machine

However all of these containers have one restriction. Only welding settings for the Passes of one kind of Welded Structure can be loaded on one machine simultaneously.

But what if we have to weld Passes for different types of Welded Structures on one machine?

For this purpose, we’ve added another type of container – Welding Program.

The Welding Program is set up for a particular type of machine and contains Welding Tasks (one or more).And Tasks can include welding Passes for constructions of various kinds. When creating the Program, the Tasks of the pre-manufactured Task Groups are taken separately for each Welded Structure type.

After uploading the Welding Program on the machine you can (according to the scenario of the Program) weld the Passes for various welding structures.

Work Order – a planning tool

During the production it is often necessary to execute certain works on certain machines on specific days. For this purpose in Q.MACS containers are used – Work Orders (or assigned Tasks) – analogous to the Operating Procedure, which is used in real production.

When refilling the Order, a specific welding scenario (single Task or Program) is being selected. Further the machine and the execution date are defined. On the scheduled day, the Order automatically appears in the list of scenario objects on the specified machine.

In Order you can include additional information, related to the welding (e.g. specifying the customer, the order number, serial number, etc.). This information is stored together with the parameter values of the executed welds and can be used for further analysis.

As you see, despite the apparent complexity all listed data items find a practical use in your work.

In addition, you also receive/get other benefits, such as:

- Reusing an already completed work in various combinations

For example you can apply a previously developed scenario for a welded Joint (Joint Technology) to weld various types of Constructions.

- Synchronization of changes within the settings of various objects

In case you need to change settings for a particular element (e.g. Job), youwon’t have to go through all the containers which use this element, in order to update its status. The system will do this automatically!

- Convenient loading of settings on the welding machine

You can upload the machine not only with separate Jobs, but also the whole Job groups (scenarios) at once, depending on the type of task you’d like to perform.

- Flexible quality analysis of finished welds

You can make meaningful representations, to analyze the results of your work, by selecting, grouping and aggregation of stored parameters for different aspects.

Of course you do not have to use all of the opportunities Q.MACS offers you at once. Finally, you can handle just the Jobs (so how is it done in other similar systems).

But if you “risk” once making use of the full set of functions of Q.MACS, then it is unlikely that you will continue to do without them.

So try it out.

Because, as they say: No risk no fun!

Isn’t it?